Stainless steel has been widely used due to its high corrosion resistance and decorative properties, especially in medical appliances, food industry appliances, tableware, kitchen utensils, etc. Stainless steel appliances should be corrosion-resistant, bright and clean, and the surface of the appliance should not be attached with substances that are toxic to the human body. Therefore, the requirement for the surface treatment of such tools is to completely remove the harmful substances on the surface.

The materials required for stainless steel polishing generally include: "polishing wax, hemp wheel, nylon wheel, cloth wheel, wind wheel, wire cloth wheel" and so on.

Surface finish is an important element in any specification of stainless steel regardless of the intended use. For those applications where appearance is important, finish is a design element and must be specified. Like polished mirror or brushed no.4 / hairline finish. Of course, relevent tools will be needed to assist in finishing.

How much does a 4x8 sheet of stainless steel cost? This is a often asked question by stainless steel sheet importers, buyers or traders.

It is very simple, first you have to tell us the material of the product you need, 201, 304, 430 or 316L, then tell us the thickness of the product you need, and the tolerances you can accept, then the size, the regular size 4X8, or other indefinite feet, the most important thing is the surface of the product, different surfaces have a great impact on the price, because the surface treatment of the product varies, therefore, we need to know your surface requirements exactly. If you don't know, we can give our advice and tell you which surface fit you well. Finally, I need to know the quantity, the normal weight of one pallet is about 2 metric tons. With these elements, we can get you the price.

However, since international trade involves transportation, if the quantity is not large, we can help you to deliver to Guangzhou, or your agent's warehouse in Wuxi, or urgently need the goods, we can also send it by air. If it is an entire container, it is relatively easy to quote the price, and it is more convenient for both of us.

For more, you may email us at thomas.goldeco@gmail.com, or submit your inquiry through our online inquiry system, we would love to quote you our best price, and assist you in your business.

In view of the possible rusting of brushed colored stainless steel sheets, there are currently difficult to have professional judgment and effective solutions. Some companies said that all brushed stainless steel sheets, including (brushed titanium/rose gold, brushed black titanium, etc.), 201 or 304 material, it is required to have anti-fingerprint treatment, strengthen the anti-oxidation performance, solve and improve the anti-rust and color loss problems, in order to be more conducive to future cleaning and maintenance, improve product quality. However, if the customer only pays attention to the cost and does not follow the recommendations, the risk of rust, color loss and economic loss will be borne by the customer.

This notice is to avoid the quality problem. In fact, the same is true for telling people 304D and 304. The customer has the right to choose and know. The test is whether the supplier fulfills the integrity issue of the responsibility.

The stable performance of the protective film is within three months from the factory. Pay attention to the storage time of the plate and the sequence of successive batches; prevent the high temperature of the sun before the protective film is torn, and tear off as soon as possible after the installation and acceptance; the storage condition of the sheet should be clean, dry and ventilated; during the processing and installation and after the installation, it is necessary to pay attention to the protective measures on the surface of the sheet to avoid contact with the mud, oil, acid and alkali ignorance; Avoid scratching of sharp objects and man-made damage during handling.

Colored stainless steel sheets (such as rose gold, titanium gold, titanium black, copper sheet, etc.) stocks best use time is three months; due to the existence of different batches of plates, there will be a little chromatic aberration of objective conditions, refer to the factory label, Choose the same batch to use; color sheet s is used for engineers, please pay attention to confirm that the sheets has no color difference.

The world is developing as world link is getting stronger, it is to get stainless steel sheet products, by relying on fast international shipping service, you can get the stainless steel goods at every corner in the world, or by air for a finished product, days you will have what you want.

And also there are stainless steel suppliers in South Africa, in Pinetown, Gauteng, Centurion, If you want to get the decorative stainless steel sheet sizes, perforated stainless steel sheet sizes, thickness and price list which is not available in your local market, contact us, we will get you everything you need, including sheet metal fabrication.

We are your factory in China, integrate resources for you!

Protective film is designed for providing temporary protection to product surfaces during production, transportation and fabrication. Most protective film is made with plastic film (PE) with adhesive (Water-based Acrylic ) coated on its back side.

If applied indoor without heating, PE film can be left on products for several years without degrading. If continuously exposed to the sun, normal PE protective film will degrade after 3 months. UV resistant PE protective film can last for half a year, or one year or one and half a year outside in the sun. A lot of protective films haven't been peeled off in time. Thus, the PE film are degraded, burned, twice burned and leaves residues that is ugly and difficult to be removed.

Adhesive also will age as time goes by. Water based acrylic adhesives are pressure, UV light, dwell time and heat sensitive adhesives. The more you have of each of these variables, especially in combination with each other, the "better" these adhesives perform that they won't let go of either the surface being protected nor the carrier film they rode in on.

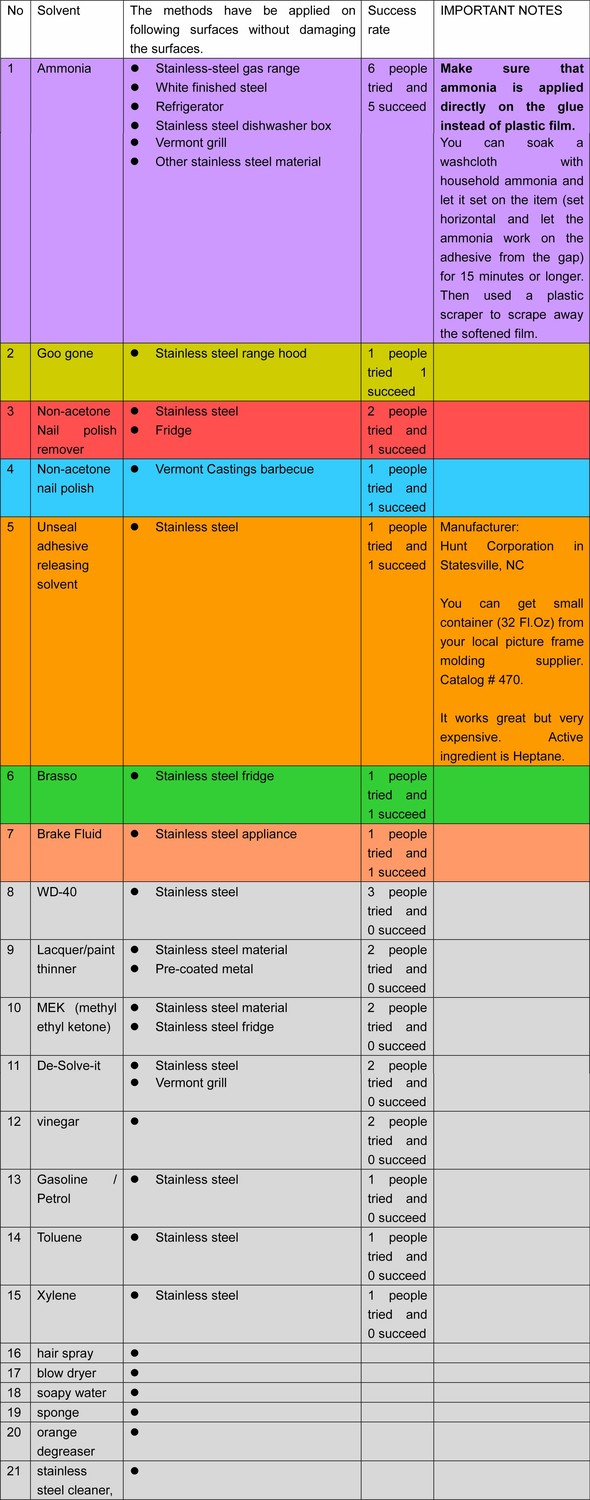

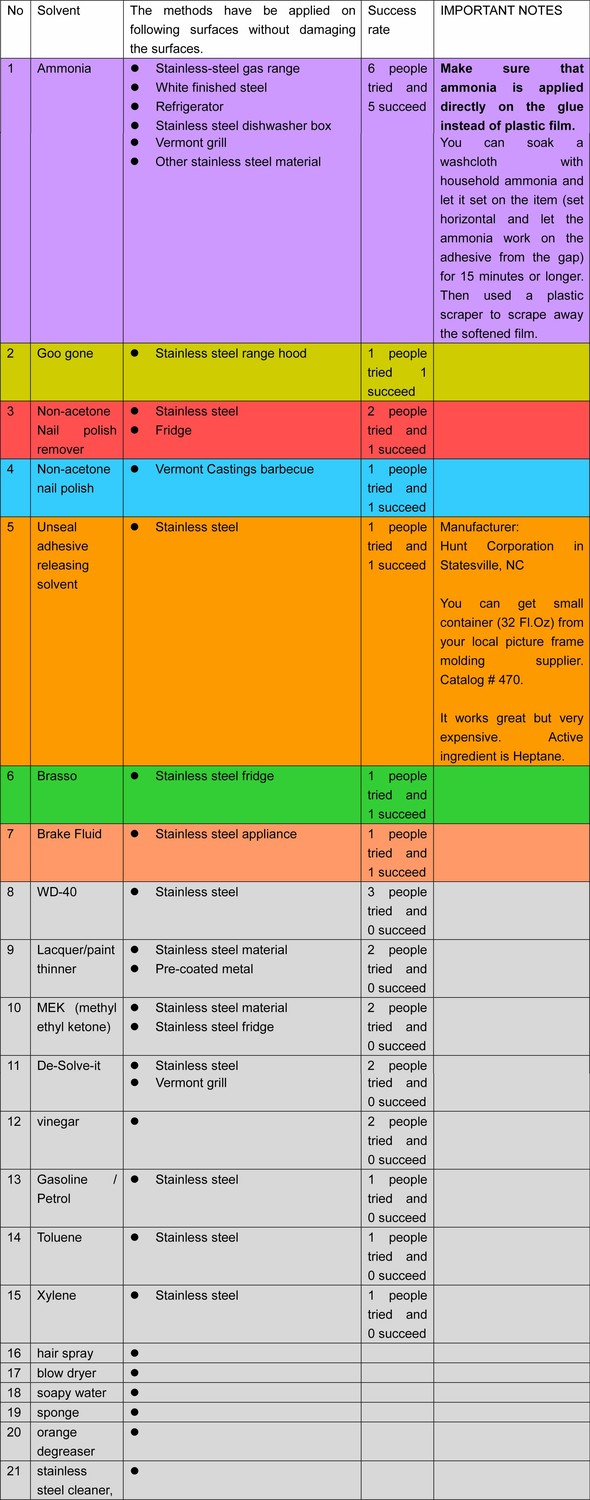

So when we talk about removing the residue of protective film, we need to check that the residue is plastic film & adhesive or only adhesive. Because the plastic film is neither permeable nor dissolvable while adhesive may be dissolved by some solvents. Maybe residue on your item can be cleaned with one solvent, but you fail. That is probably because you are not applying the solvent on the plastic film instead of adhesive.

Even it is difficult to remove the residues, there are still people who have tried many methods to overcome the difficulties and some of them really did it. In this article, we have collected some methods that have been tried by many people and sort out. Hope it can help more people to remove protective film residues easily and quickly.

Solution 1, Recommended methods for removing residue of plastic film and adhesive.

If the residue is plastic film and adhesive together, recommend firstly find mechanical method of removing the film. And than refer to Situation 2 to remove adhesive residue.

Solution 2, Solvents recommended for dissolving adhesive residue only:

Have you tried any method or solvent mentioned above to remove protective film residue? Does it work or not?

Do you have other methods that can remove protective film residue effectively? Welcome to share with us by writing to us. Thank you!

Dear Valued Customers,

For better using of stainelss steel sheets, here following we will share you some points on how to avoid problems during using.

1. Don't put the stainless steel sheet with protective film under the sun.

2. Remove the plastic film immediatly after installation where cement were used.

3. Keep the surface clean and dry, especially for grade 201.

4. Use clean water and soft sponge clean the dirty part. Don't use solvent, especially for black colored sheet.

5. Use cold tig welding for colored sheets, it will help remain the colors.